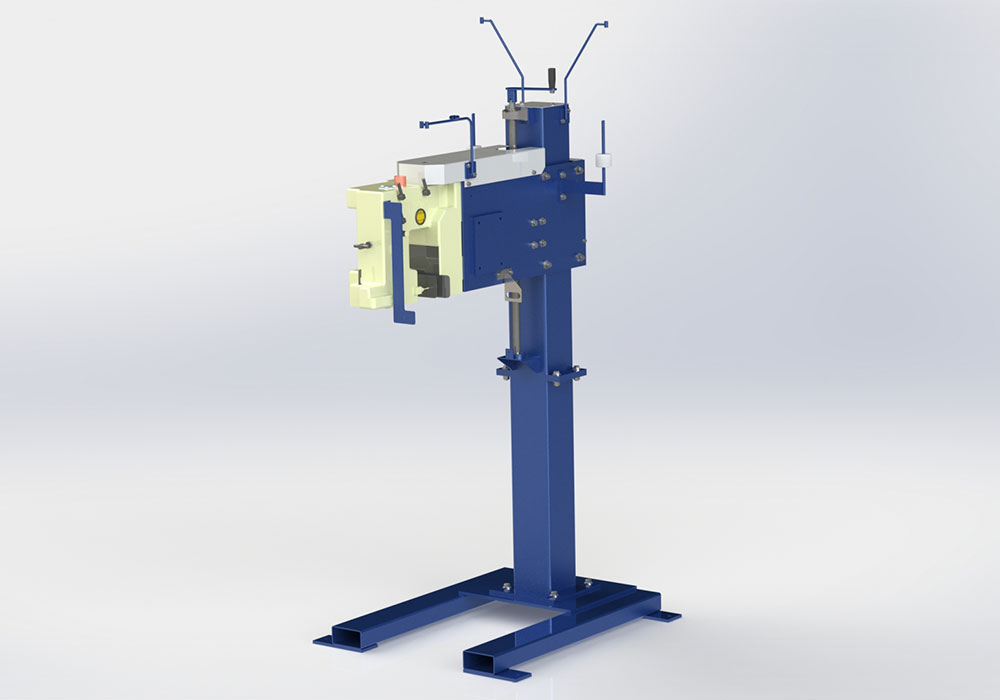

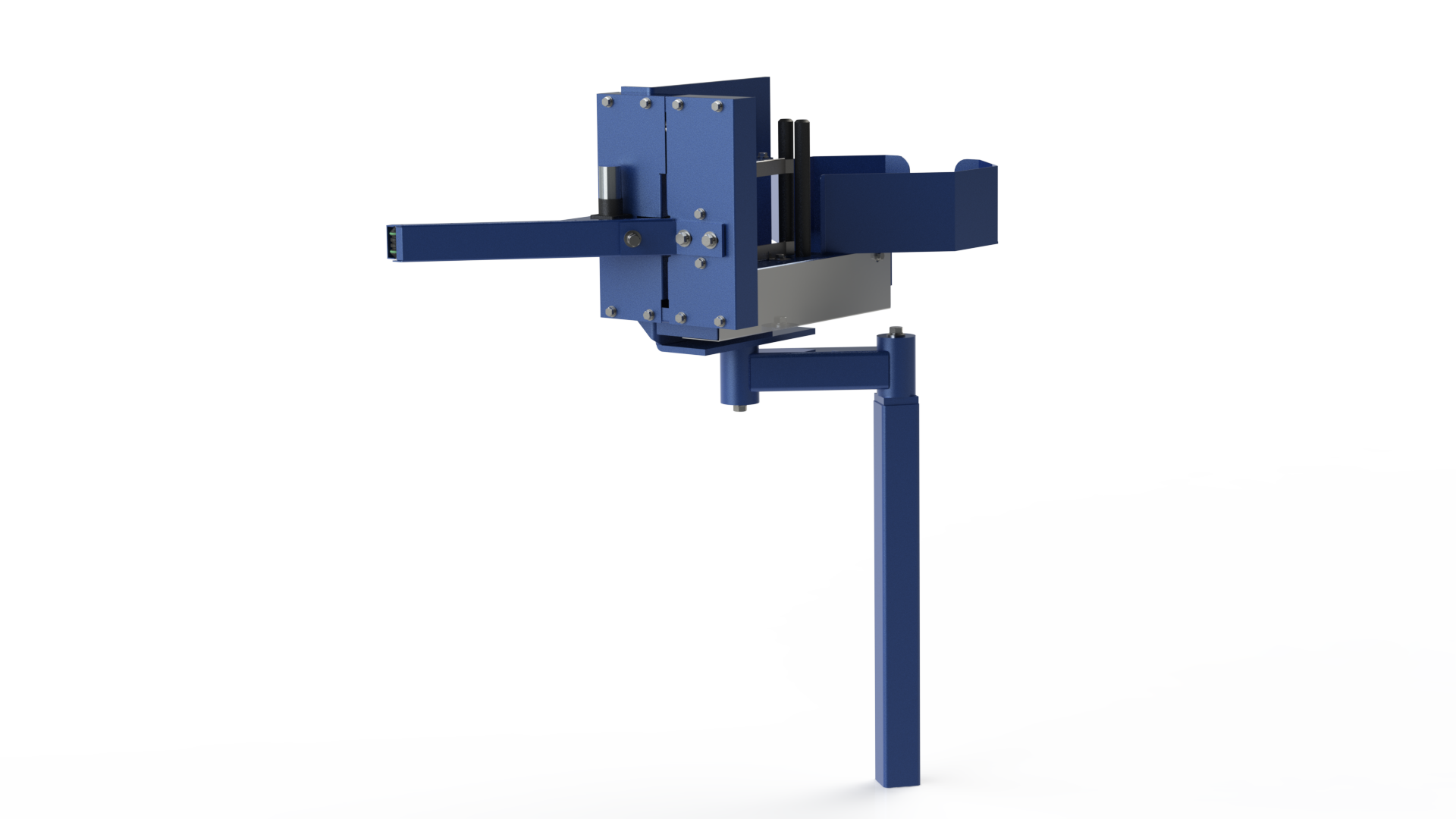

The Morray by The Sack Filling Company range of Sack Closing Equipment is a great leap towards total automation of your packing line when used in conjunction with conveyor systems and bagging units.

- Portable, medium and heavy duty stitchers.

- Precision sewing head and conveyor speed synchronization.

- Automatic stitcher start / stop and thread cut off.

- Fully compatible with the Sack Filling Company range of sack conveyors.