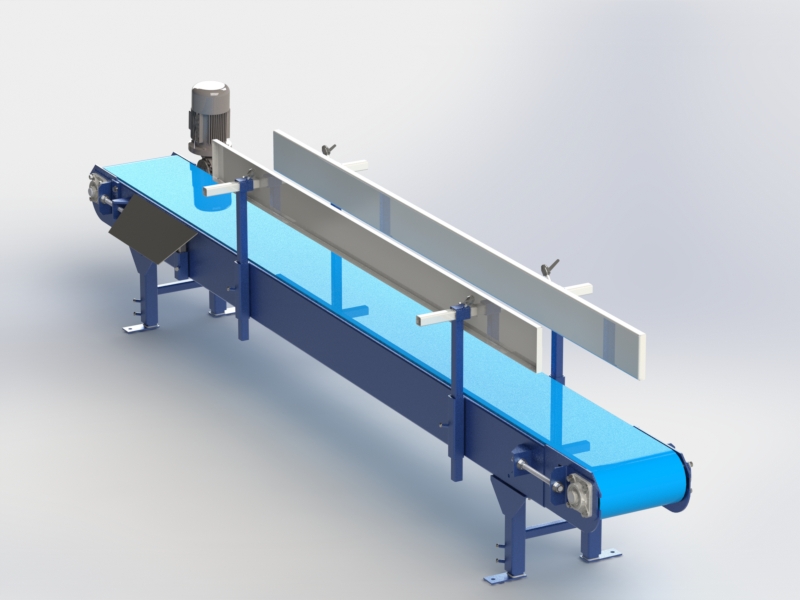

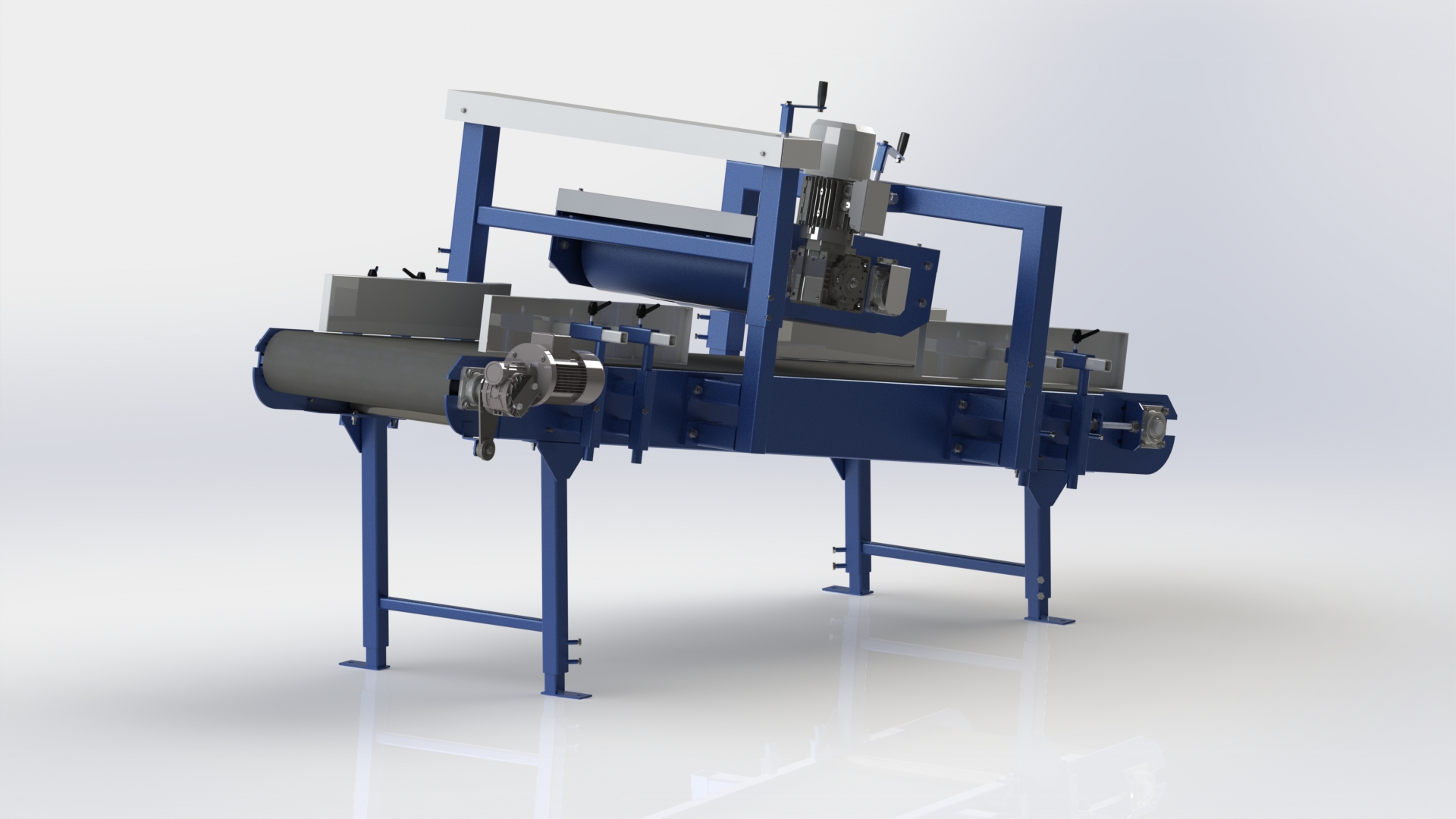

The Sack Filling Company’s range of Sack Conveyors are tailored to length, width and control configuration to suit the requirements of any material transport system- from simple stitching lines to fully automated production and packing facilities. All Sack Conveyors are available in rubber belt, Intralox®, stainless steel slat band and plastic slat band to meet the needs of your product

Sack Conveying Systems

Let’s get started on your project…

Get in touch today and find out how we can help you with your automation project.

Contact

The Sack Filling and Robot Palletising Company Ltd.

Walthambury House

Witham Road

Cressing

Essex

CM77 8PD

UK

Accreditations

©Copyright The Sack Filling and Robot Palletising Company Ltd. . All Rights Reserved | Cookie Policy | Web Design Braintree by Nebulas Website Design